Rubber for the Rail Industry

Our role in the rail industry

The Rail industry has a market value of over £24.2 billion and is forecasted to hit £30.6 billion by 2026. Public transport connects millions of people across the globe; as such the rail network must strive to provide efficient, consistent and premium service, setting the highest standards of performance for people and freight.

From light rail and subway systems to newer high-speed rail systems like the Chinese HSR systems and French TGV, rail is arguably the future's most sustainable mode of transportation. In the UK, there is a vast rail network connecting many towns and cities and many of them namely Manchester, have invested heavily in public transport systems.

Rubber applications for rail

Ultimately, it’s paramount that the trains run smoothly, here are the most common applications that help the rail industry:

- Door Seals

- Vibration Dampening

- LED Seals

- Trolley Bumpers

- Rail Carriage Bumper Protectors

- Electrical Gaskets

How does rubber help the railways

The need for rubber components that are durable, wear-resistant and cost-effective is constant both domestically and abroad. Rubber is used in a number of internal and external applications in rail to maintain the structural integrity of vehicles. All components must be corrosion resistant and fit for extreme environmental conditions.

Rubber applications for rail

Ultimately, it’s paramount that the trains run smoothly, here are the most common applications that help the rail industry:

- Door Seals

- Vibration Dampening

- LED Seals

- Trolley Bumpers

- Rail Carriage Bumper Protectors

- Electrical Gaskets

How does rubber help the railways

The need for rubber components that are durable, wear-resistant and cost-effective is constant both domestically and abroad. Rubber is used in a number of internal and external applications in rail to maintain the structural integrity of vehicles. All components must be corrosion resistant and fit for extreme environmental conditions.

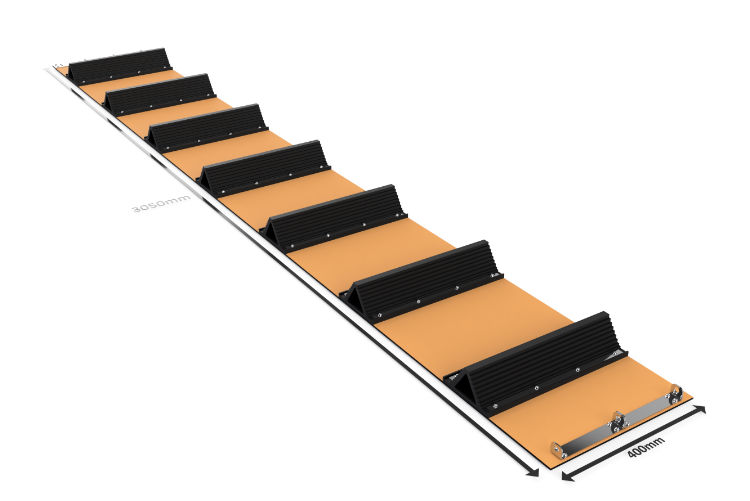

No more slips with Rollaway portable safety stairs

The Rollaway has been designed to prevent slips and falls in outdoor settings, helping workers safely navigate slippery or uneven surfaces like banks, ditches, quarries and hills. Your Rollaway will be custom made exclusively by us and can be produced at any length.

More about The Rollaway

Did you know...?

Despite the huge advances in the design and manufacture of railway rolling stock in the last decade, the sealing, durability and impact absorption characteristics of EPDM extrusions and mouldings, continue to be deployed on railways around the globe. As a supplier to the UK's operators and manufacturers, we continue to play our part in the ongoing modernisation and maintenance of the UK's rail, light rail and underground networks.

The Walker Rubber Difference

Delivery

Rubber products manufactured to order with industry leading turnaround times.

Support

Not quite sure what you need? Our team are on hand to provide fast, high-quality expertise with years of experience to back it up.

Service

Your journey with us starts in sales. Like our exceptional manufacturing lead times, our sales team is no different. They will guide you through the process every step of the way. We are proud to say 90% of enquiries are quoted on the same day ensuring there is no delay in getting your project with us underway.

Quality

With our right first-time ethos, combined with only using premium materials from trusted sources, the quality of our rubber products are the best in the business.

Our Capabilities

Extrusion

We are experts in the manufacture of rubber extrusions. Our limitations are very small we can produce extrusions from 1m to 10,000m in length or 1mm to 300mm across.

Rubber ExtrusionsGaskets

Our selection of cutting machinery enables us to be accurate and precise, meeting the required specifications for our customers.

Rubber GasketsMouldings

Most moulding requirements are unique to each customer. We supply a comprehensive range of mouldings in a variety of compounds: EPDM, Neoprene, Natural, Nitrile Silicone, Viton, Polyurethane and TPE.

Rubber Mouldings

Bonding

One of our more unique capabilities. We can bond together multiple types of rubber sheet to create your ideal material.

Rubber Bonding

Tooling

We have the capability to manufacture tooling inhouse, turning your ideas into reality with a short but cost-effective turnaround

Rubber Tooling