Rubber for the Water Industry

Our role in the water industry

The water industry value is forecasted to hit £247.6 billion by the end of 2022. By 2029 the market value is set to increase reaching £401.47 billion. The water industry provides clean water for domestic and commercial consumers. It maintains and improves sewage treatment processing plants and operates thousands of miles of pipelines and hundreds of pumping stations over a vast geographical area. Protecting public health and maintaining this infrastructure is vital to ensure a safe and secure water supply. Seals, the rubber kind, are a vital component for the residential and commercial sectors, with both municipal water and waste water.

Walker Rubber supporting the water industry

As it should be, there are very stringent regulations for water treatment processes. We provide specialist sealing solutions and temporary-access ladders, which can be used across the industry.

We have a comprehensive range of rubber components to choose from. These include: WRAS (Water Regulations Approval Scheme) certified for drinking water applications and polymeric compounds specifically designed for abrasion and chemical resistance. Our WRAS-approved EPDM known for its high performance and quality can be used for pipeline gaskets and composite seals.

View Our WRAS-approved extrusions profilesRubber Applications for the water industry

It is important to get the correct rubber solution, here are some of the more common applications of rubber for the water industry:

- Non-leak hosing

- Non-leak extrusions

- Oil seals

- Pipeline gaskets

- Composite seals

- Suction hose

Our rubber components are WRAS approved and can be custom made and ready for you.

Our CapabilitiesWalker Rubber supporting the water industry

As it should be, there are very stringent regulations for water treatment processes. We provide specialist sealing solutions and temporary-access ladders, which can be used across the industry.

We have a comprehensive range of rubber components to choose from. These include: WRAS (Water Regulations Approval Scheme) certified for drinking water applications and polymeric compounds specifically designed for abrasion and chemical resistance. Our WRAS-approved EPDM known for its high performance and quality can be used for pipeline gaskets and composite seals.

View Our WRAS-approved extrusions profilesRubber Applications for the water industry

It is important to get the correct rubber solution, here are some of the more common applications of rubber for the water industry:

- Non-leak hosing

- Non-leak extrusions

- Oil seals

- Pipeline gaskets

- Composite seals

- Suction hose

Our rubber components are WRAS approved and can be custom made and ready for you.

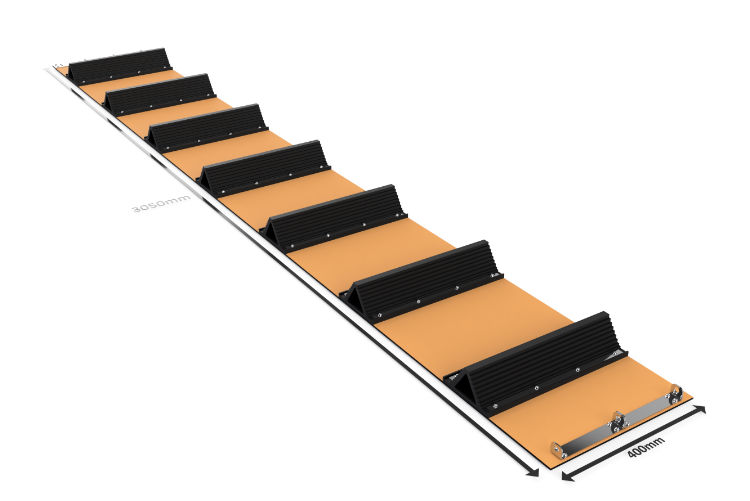

Our CapabilitiesNo more slips with Rollaway portable safety stairs

The Rollaway has been designed to prevent slips and falls in outdoor settings, helping workers safely navigate slippery or uneven surfaces like banks, ditches, quarries and hills. Your Rollaway will be custom made exclusively by us and can be produced at any length.

More about The Rollaway

Did you know...?

Our manufacturing plant is based in Norwich. Due to our reputation for rapid response times and exemplary service we were approached by Anglian Water. Our CNC (Computer Numerical Control) cut gasket service, coupled with the amazing support from our partners in logistics, means that we can often manufacture and deliver components in hours instead of days. The result was that the water services restored to consumers quickly and cost-effectively with minimal disruption to supplies and the local economy.

The Walker Rubber Difference

Delivery

Rubber products manufactured to order with industry leading turnaround times.

Support

Not quite sure what you need? Our team are on hand to provide fast, high-quality expertise with years of experience to back it up.

Service

Your journey with us starts in sales. Like our exceptional manufacturing lead times, our sales team is no different. They will guide you through the process every step of the way. We are proud to say 90% of enquiries are quoted on the same day ensuring there is no delay in getting your project with us underway.

Quality

With our right first-time ethos, combined with only using premium materials from trusted sources, the quality of our rubber products are the best in the business.

Our Capabilities

Extrusion

We are experts in the manufacture of rubber extrusions. Our limitations are very small we can produce extrusions from 1m to 10,000m in length or 1mm to 300mm across.

Rubber ExtrusionsGaskets

Our selection of cutting machinery enables us to be accurate and precise, meeting the required specifications for our customers.

Rubber GasketsMouldings

Most moulding requirements are unique to each customer. We supply a comprehensive range of mouldings in a variety of compounds: EPDM, Neoprene, Natural, Nitrile Silicone, Viton, Polyurethane and TPE.

Rubber Mouldings

Bonding

One of our more unique capabilities. We can bond together multiple types of rubber sheet to create your ideal material.

Rubber Bonding

Tooling

We have the capability to manufacture tooling inhouse, turning your ideas into reality with a short but cost-effective turnaround

Rubber Tooling