Rubber Bonding & Fabrication

Delivering rubber bonding in industry leading delivery times

Walker Rubber is capable of bringing your rubber bonding ideas to the forefront. Take a chance on us and we will deliver.

Walker Rubber's rubber bonding service will meet your needs in no longer than two weeks. We offer some the most unique products like Fire fighters pole mat and Horse box ramp mat.

Do you require an extra-large gasket bonded together in sections? Or perhaps you're looking for a unique rubber/foam/rubber laminate material offering extra wear-resistance whilst maintaining a cushion? If you supply us with your design, we will endeavour to find a solution.

Bonding does not have to be constrained to materials we supply. We are also capable of bonding our rubber to metal. Alongside our ability to bond rubber to metal we can also bond all our rubber materials to a variety of other supplied materials

Our 80 years of knowledge combined with our state-of-the-art equipment ensures we will not to be bested on quality and lead times.

Our Rubber Bonding Capabilities

We provide a comprehensive rubber bonding service to manufacture and supply custom rubber solutions, including:

- Rubber-to-rubber bonding: ideal for creating multiple thicknesses outside standard sheet sizes and custom seal frames

- Rubber-to-foam bonding: perfect for cushioning and wear-resistant applications

- Rubber matting-to-foam bonding: for heavy-duty flooring or industrial applications

- Rubber-to-metal bonding: commonly used with mild steel, aluminium, and other metals

- Foam-to-metal bonding: for industrial machinery, cushioning, or gaskets

We work with a wide variety of rubber materials, including:

Our Rubber Bonding Service

Our bonding services support a variety of industries and applications:

- Thin rubber sleeves and rubber tube sleeves for industrial and mechanical use

- Rubber-to-metal plates for machinery, automotive, and structural applications

- Firefighters pole mats and horse box ramp mats for safety and cushioning

- Rubber chutes, rubber cones, and custom rubber bonded extrusions for specialised industrial needs

- Rubber-to-metal bushes used widely for their anti-vibration and shock absorption in industrial applications

We can also bond rubber to supplied materials, providing custom laminates that combine rubber, foam, and metal to meet specific wear, cushioning, or chemical-resistance requirements.

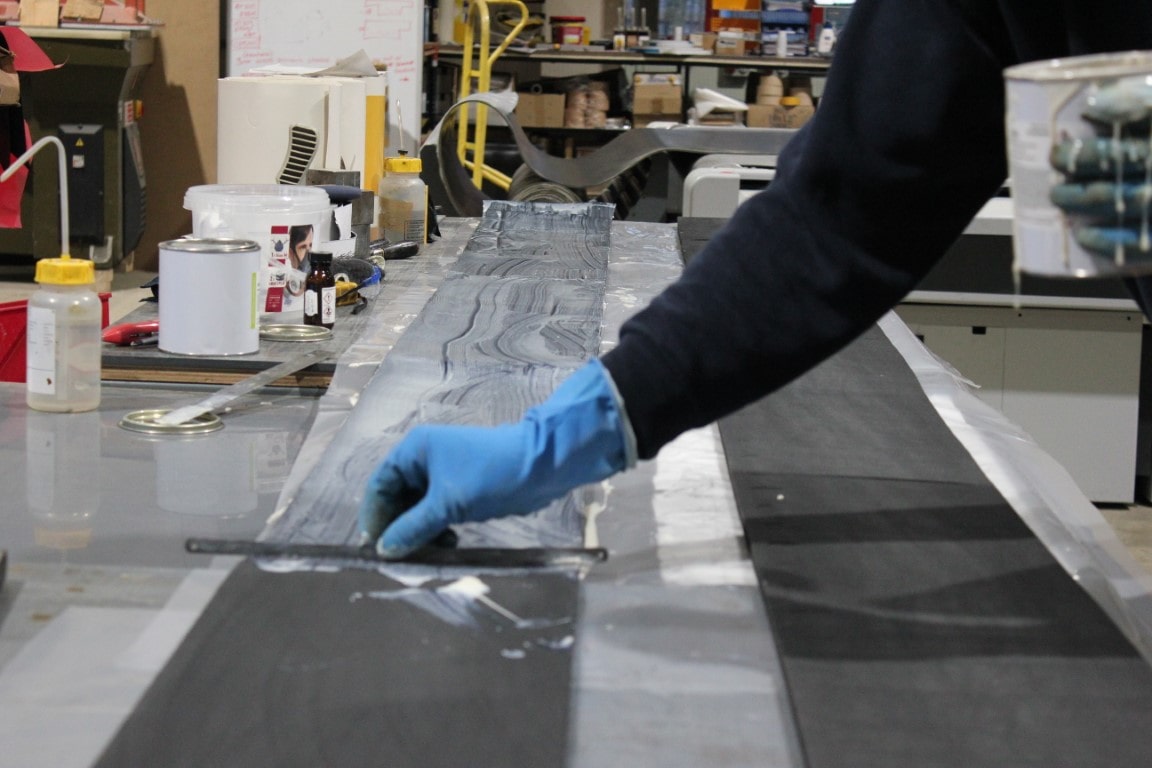

How Our Rubber Bonding Works

At Walker Rubber, our rubber bonding service is built on over eight decades of experience. We use advanced adhesives and techniques to ensure every bond achieves maximum strength and durability to live up to the demands of your application.

Whether bonding rubber to metal, foam, or other rubbers, we adapt our manufacturing methods to suit your needs. This helps to ensure long-lasting adhesion between the materials and gives excellent resistance to environmental stresses.

Surface preparation

We clean and treat each material to ensure the optimal foundation for adhesion.

Apply adhesives

We apply high-performance bonding adhesives, chosen specifically for the rubber and substrate combination.

Apply heat & pressure

Using controlled heat and pressure, we then cure the assembly to form a uniform, reliable bond.

Custom Rubber Sleeves & Tube Sleeves

We specialise in the production of rubber sleeves, including thin rubber sleeves and rubber tube sleeves, tailored for a wide variety of industries. These sleeves are ideal for protecting shafts, providing flexible seals, or acting as vibration dampeners in machinery.

Each sleeve is manufactured to your exact dimensions and UK-sourced, premium rubber material suited to your application, such as EPDM, neoprene, nitrile, and silicone. Whether you require a thin rubber sleeve for lightweight mechanical applications or a reinforced rubber tube sleeve for high-pressure environments, we can supply a solution that meets your needs.

Our expert engineers will help you select the right compound, bonding method, and wall thickness to achieve the perfect balance of durability and flexibility.

The Walker Rubber Difference

Delivery

Our rubber bonded products are manufactured to order with industry-leading turnaround times. Bonding can take between 5-10 days, including vulcanisation.

Support

Not sure exactly what you need? Our team of experts offers fast, high-quality guidance, backed by decades of experience to recommend the best rubber bonding solutions.

Service

We quote 90% of enquiries on the same day, guiding you through every step of the bonding process.

Quality

With a “right first-time” ethos and premium materials from trusted suppliers, the quality of our bonding rubber solutions is unrivalled.

Learn More About Bonding Rubber

Our knowledge hub is packed with information to help you in your next project! Visit the page below to get a more in-depth look at bonding rubber.

Bonding rubber Rubber adhesives